| Price: | Negotiable |

| Min.Order: | 1 |

| Supply | 613 |

| Delivery: | Shipment within 1 days since the date of payment |

| Address: | China Beijing |

| Valid until: | Never Expire |

| Updated on: | 2024-11-19 14:35 |

| Views: | 539 |

B12 Chayoyangmenwai St. Beijing, China

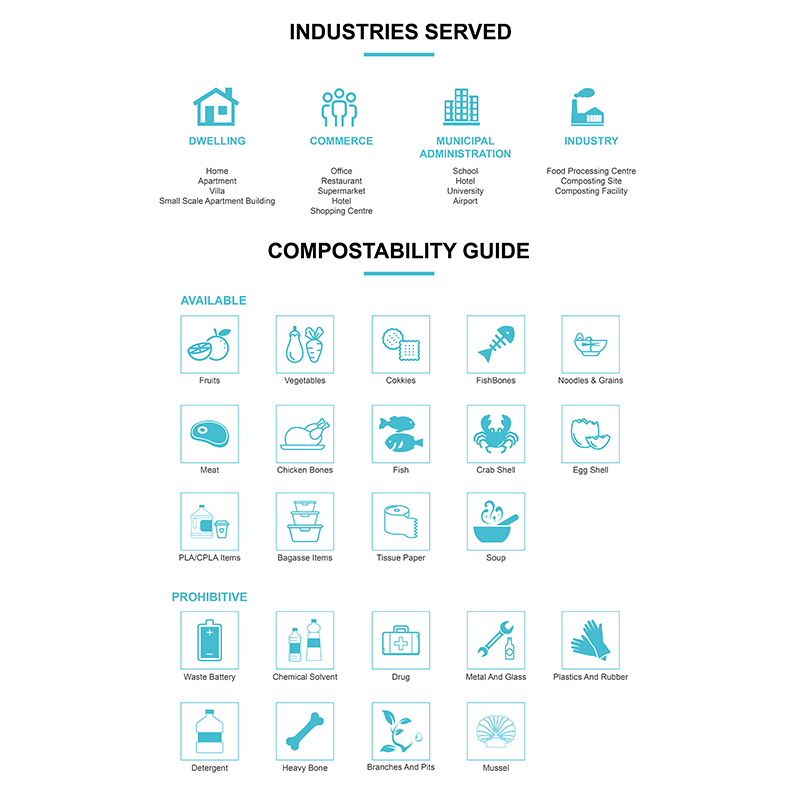

1. Product Introduction of High Dehydration Rate Low Energe Consumption High Oil Extraction Rate Oil Water Separator

In the catering industry and families, the production of kitchen waste has become a problem that can not be ignored. In particular, the oil composition in it not only causes difficulties in the waste disposal process, but also has a negative impact on the environment. The HONbase High Dehydration Rate Low Energe Consumption High Oil Extraction Rate Oil Water Separator, as a technologically advanced equipment, can effectively separate oil and water from kitchen waste, which provides strong support for the recycling and environmental protection of waste treatment.

Basic principle

The basic principle of the oil-water separator is based on the difference in density between oil and water. Oil is lighter than water, so it can be separated naturally under the right conditions. In addition, the separator usually combines a variety of separation technologies, such as gravity separation, centrifugal separation, etc., to improve the processing efficiency and effect.

Specific separation method

Gravity separation

Gravity separation takes advantage of the difference in density between oil and water, with heavier water sinking to the bottom and lighter oil floating to the surface. At rest, oil gradually accumulates on the surface of the liquid, forming an oil layer.

Centrifugal separation

Centrifugal separation separates oil and water in a mixed liquid by centrifugal force generated by high-speed rotation. Centrifugal force causes the denser water to move outwardly and the less dense oil to concentrate inwardly.

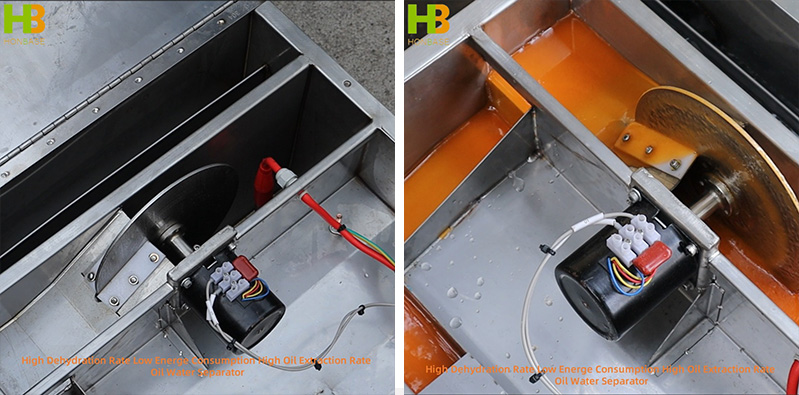

Filtration separation

The solid particles in the oil-water mixture are filtered out through a filter screen or filter membrane. The filtered liquid can be further separated from oil and water.

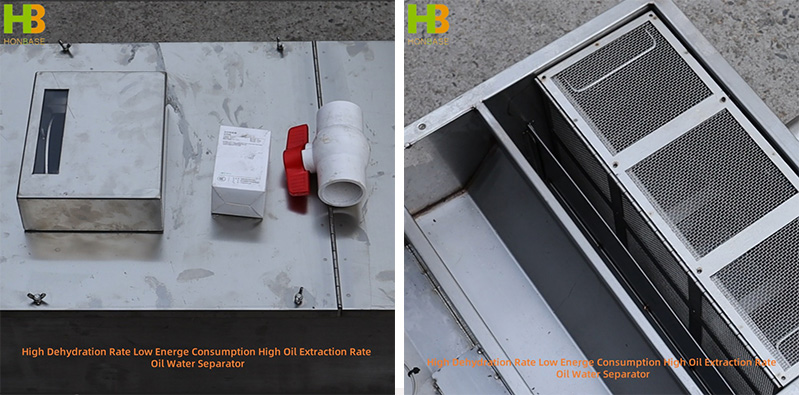

Equipment composition

An oil-water separator usually consists of the following parts:

Feed system: The oil-water mixture is fed into the equipment, which may be equipped with a crusher to improve separation efficiency.

Separation system: Separation of oil and water by gravity, centrifugation or filtration.

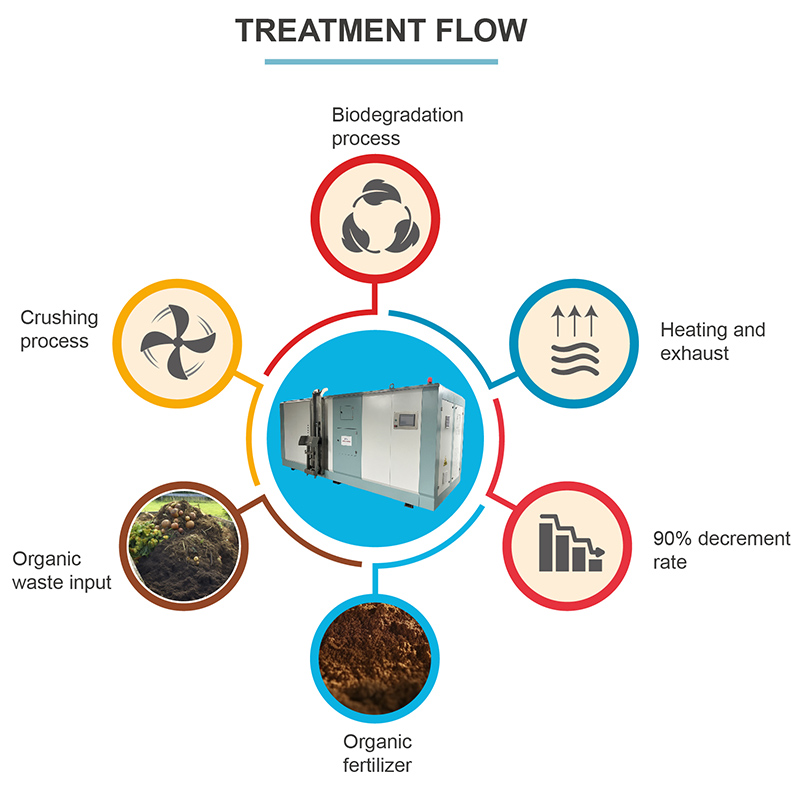

Control system: Automated operation and monitoring.

Discharge system: the separated oil and water are discharged separately.

The promotion and application of the HONbase High Dehydration Rate Low Energe Consumption High Oil Extraction Rate Oil Water Separator, helps to raise public awareness of environmental protection, promotes the popularity of green lifestyle. With the wide application of these equipment, people are more and more aware of the importance of garbage classification and reduction, so that they pay more attention to environmental protection in their daily life, to reduce unnecessary waste and pollution. This awareness is of great significance for building a resource-saving and environment-friendly society.

2. Product Parameter (Specification) of High Dehydration Rate Low Energe Consumption High Oil Extraction Rate Oil Water Separator

| Product Specifications | |

| Brand Name | Oil Water Separator A |

| Model Number/Specification | HB-OWS-A |

| Automation | Automation |

| Treatment | Pre-treatment |

| Applicable Objects | oil-water mixture |

| Feed Type | Continuous |

| Frequency (Hz) | 50Hz |

| Voltage (V) | 220V |

| Rated Power Consumption/Electric Heating Power | 528Kw |

| Role | Pre-treatment |

| Machine Material |

Stainless steel |

| Grinding Chamber Material |

Stainless Steel SUS 304 |

| Width (mm) | 756 |

| Height (mm) | 266 |

| Deep (mm) | 445 |

| Input Capacity/Production Capacity | 2000KG/H |

| Treatment Time | Real time |

3. Product Feature And Application of High Dehydration Rate Low Energe Consumption High Oil Extraction Rate Oil Water Separator

The advantages and characteristics of the HONbase High Dehydration Rate Low Energe Consumption High Oil Extraction Rate Oil Water Separator.

Improve processing efficiency

The oil-water separator can quickly and efficiently separate the oil-water mixture, which greatly improves the efficiency of waste treatment, especially for the needs of catering and industrial fields.

Resource recycling

Through efficient separation, the oil and water separator can recover the oil, and the oil can be used to make biodiesel or other industrial uses, further promoting the recycling of resources.

Reduce environmental impact

The oil-water separator reduces the oil pollution to the environment, reduces the oil content in the wastewater treatment process, helps to improve the water quality and protect the ecological environment.

Comply with environmental regulations

With the increasingly stringent environmental regulations, the use of oil and water separators helps catering and industrial enterprises operate in compliance and avoid legal liability due to grease problems.

Automation and intelligence

Future oil and water separators will increasingly use automation and intelligent technology, capable of remote monitoring and automatic adjustment to improve work efficiency and reduce manual intervention.

Ecological sustainable development

With the global emphasis on sustainable development, oil-water separators, as environmental protection equipment, will play a greater role in resource recovery and environmental protection, and promote the development of green economy.

4. Product Details of High Dehydration Rate Low Energe Consumption High Oil Extraction Rate Oil Water Separator