| Price: | Negotiable |

| Min.Order: | 1 |

| Supply | 349 |

| Delivery: | Shipment within 1 days since the date of payment |

| Address: | China Beijing |

| Valid until: | Never Expire |

| Updated on: | 2024-11-19 14:35 |

| Views: | 122 |

B12 Chayoyangmenwai St. Beijing, China

1. Product Introduction of Commercial 24 Hour Cycle Solid Liquid Separator For Processing Food Waste

Around the world, the production of kitchen waste is becoming more and more serious, which has become an important challenge for urban solid waste management. With the development of economy and the improvement of living standards, the amount of kitchen waste is increasing year by year. Effective disposal of kitchen waste can not only reduce the environmental burden, but also realize the recycling of resources. The HONbase Commercial 24 Hour Cycle Solid Liquid Separator For Processing Food Waste plays a key role as an important equipment for kitchen waste disposal.

Working principle of the HONbase Commercial 24 Hour Cycle Solid Liquid Separator For Processing Food Waste.

Basic Principles

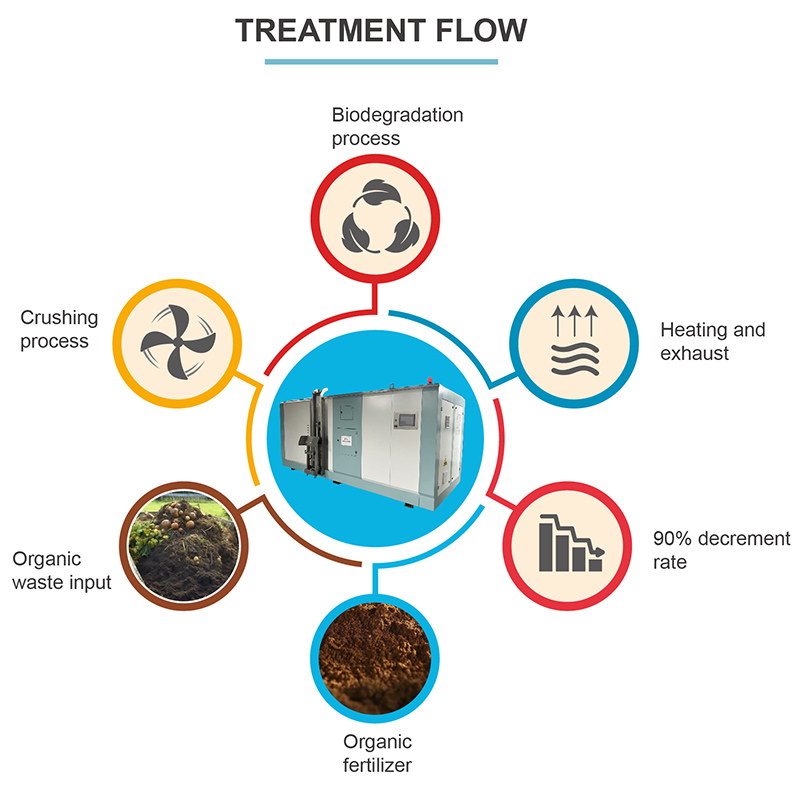

The nuclear psychology of the solid liquid separator is to separate the solid and the liquid through physical methods. Its workflow mainly includes:

Feed: The food waste is fed into the separator through the feed port of the machine, during which a preliminary crushing is usually required to improve the separation efficiency.

Separation: The separator realizes the separation of solids and liquids by centrifugation, gravity, filtration and other ways.

Collection: After the separation is complete, the solid and liquid are collected separately for subsequent processing and utilization.

Specific separation method

Centrifugal separation

The centrifuge uses the centrifugal force generated by high-speed rotation to push the solid particles outward and the liquid to concentrate in the center. This method has high separation efficiency and is suitable for dealing with large volumes of kitchen waste, such as waste generated by the catering industry.

Gravitational settlement

Gravity sedimentation separators use gravity to settle solid particles to the bottom. This method is simple and economical, but the separation effect of small particles is limited, and it is suitable for the initial treatment of viscous liquids.

Filtration

Filter separation through the filter screen or filter cloth, the solid particles are trapped on the filter material, while the liquid flows out through the material. This method is suitable for the environment with higher requirements for solid particles and can remove suspended matter well.

Equipment composition

The solid liquid separator mainly consists of the following parts:

Feed system: Used to feed waste into the separator, which may include conveyor belts, crushers, etc.

Separation system: The core component responsible for the separation of solids and liquids, usually including a centrifuge, settler, or filter.

Control system: Automatic operation of equipment, including sensors, PLC control system, etc.

Collection system: Separate solids and liquids are collected into separate containers for subsequent processing.

The application of the HONbase Commercial 24 Hour Cycle Solid Liquid Separator For Processing Food Waste in the treatment of kitchen waste has important theoretical and practical significance. Through efficient solid-liquid separation, it can not only significantly improve the treatment efficiency of kitchen waste, reduce environmental pollution, but also strengthen the recycling of resources and promote sustainable development. In the future, with the progress of technology and changes in market demand, solid liquid separators will be more and more used in the field of kitchen waste disposal and become an important help for environmental protection.

2. Product Parameter (Specification) of Commercial 24 Hour Cycle Solid Liquid Separator For Processing Food Waste

| Product Specifications | |

| Brand Name | Solid-Liquid Separator 1000 |

| Model Number/Specification | HB-SL-1000 |

| Automation | Automation |

| Treatment | Pre-treatment |

| Applicable Objects | Organic Waste |

| Feed Type | Continuous |

| Frequency (Hz) | 50Hz |

| Voltage (V) | 380V |

| Rated Power Consumption/Electric Heating Power | 16.5Kw |

| Role | Pre-treatment |

| Machine Material |

Stainless steel&Carbon steel |

| Grinding Chamber Material |

Stainless Steel SUS 304 |

| Width (mm) | 3295 |

| Height (mm) | 2000 |

| Deep (mm) | 1300 |

| Input Capacity/Production Capacity | 1000KG/H |

| Treatment Time | 3 hours |

| Reduction Rate |

50% |

| Discharge cycle(After continuous feeding every day) |

Real time |

3. Product Feature And Application of Commercial 24 Hour Cycle Solid Liquid Separator For Processing Food Waste

The application of the HONbase Commercial 24 Hour Cycle Solid Liquid Separator For Processing Food Waste in the treatment of kitchen waste brings many significant advantages, as follows:

1. Improve processing efficiency

Solid liquid separator can quickly and efficiently deal with a large number of kitchen waste, greatly improving the efficiency of waste treatment, especially in catering and municipal waste treatment, greatly reducing labor costs and time costs.

2. Resource utilization

Through efficient separation, the equipment can improve the utilization of the solid and liquid parts, so that the part of the waste is converted into a resource, the liquid takes on the value of fertilizer, and the solid can be used for composting.

3. Reduce environmental pollution

The use of solid liquid separator can reduce the accumulation and decay of garbage, reduce environmental problems such as smell, diseases and pests caused by kitchen waste, and thus improve the surrounding ecological environment.

4. Technological innovation

The introduction of new materials and advanced designs will continuously improve the performance and efficiency of solid liquid separators. For example, the use of intelligent algorithms to optimize the separation process is expected to significantly reduce energy consumption and improve separation efficiency.

5. Automation and intelligence

The application of intelligent control system will make the operation of the separation equipment more efficient and convenient, reduce manual intervention, and improve the overall processing efficiency. Future separators will likely integrate iot technology to enable remote monitoring and management.

6. Green design

The strict implementation of environmental regulations has promoted the development of solid liquid separators in the direction of green and energy saving. Research and development of low-energy, high-efficiency equipment will become the main direction of the future industry.

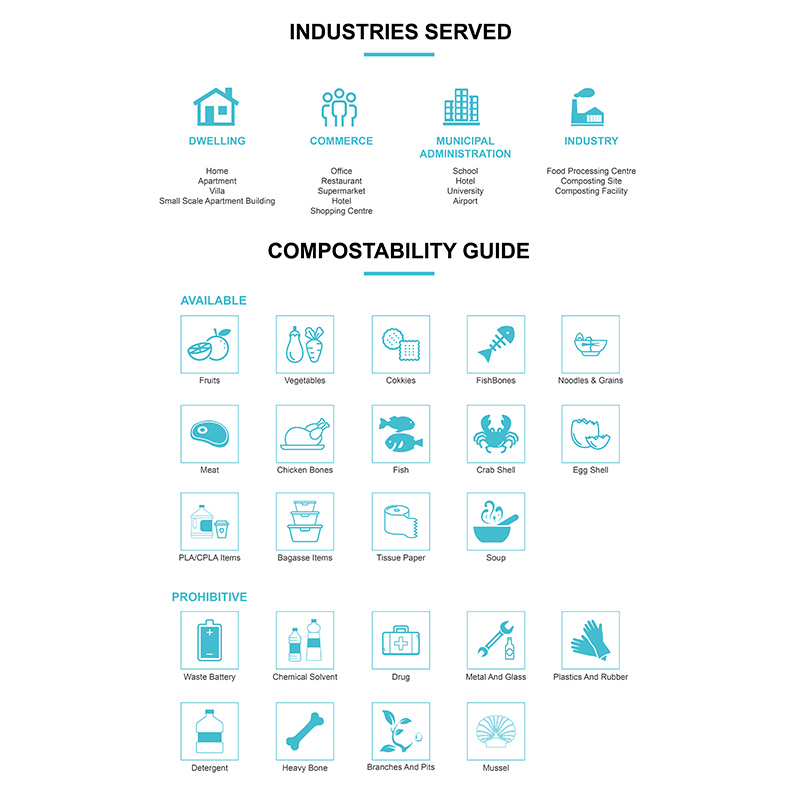

Application

Catering industry

Residential district

Recycling of renewable resources

Municipal refuse disposal

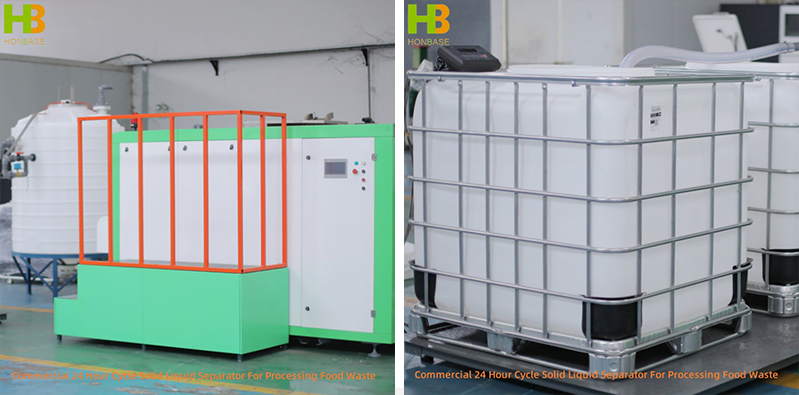

4. Product Details of Commercial 24 Hour Cycle Solid Liquid Separator For Processing Food Waste

The HONbase Commercial 24 Hour Cycle Solid Liquid Separator For Processing Food Waste improve resource utilization, good processing effect, fast processing speed, high degree of automation, simple management, good safety performance, low maintenance rate.